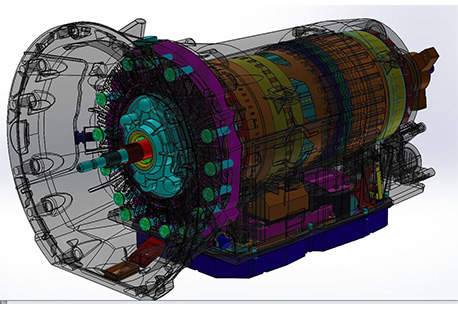

Our company can manage your conceptual to tender design by carrying out a preliminary critical feasibility review/assessment. This takes into account the component safety, reliability & maintainability in conjunction with airworthiness and applicable government regulations.

Beginning from the initial design stage through in-service support, a continuous support stream for improvement in operational costs and maintainability could be provided by us. This is accomplished by using engineering methodologies and tools that could establish a critical analysis of necessary performance standards and suggestions for innovative solutions.

Customers could also be assisted with component/part redesigns which occur due to obsolescence issues, refurbishments or upgrading. Support could also be given to create and interpret technical design documents, 2D/3D drawings & part/assembly modelling.

We combine client-specific knowledge of design & manufacturing processes while having an understanding of plastic, metallic and composite structures. Thereby, enabling us to provide you with pre-manufacturing support according to specifications and compliance to airworthiness guidelines for material choices, processes & tooling applications.

Mock-up Layout 3D Modelling

- Scaled 3D aircraft modelling for custom livery application.

- Custom layouts for exterior fuselage for identification of skin dents and other damages.

- Designing of stowage provisions for installation of portable oxygen bottles in closets/OHSB/CAS stations.

- Avionics & Electrical lines routing with structural mount installation provisions design.

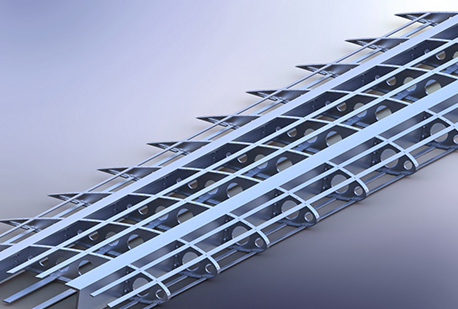

Conceptual, Preliminary Design & Design to Manufacture of Aircraft Components.

- New Component Prototype modelling per customer request & incl. Certification Standards Compliance, Feasibility & Trade-off Studies, Weight/Cost reduction.

- Detailed geometry 2D Drawing & 3D Modelling using Reverse Engineering for As-Built Aircraft Components, MRO equipment & Custom Test Rigs.

- Legacy Part Reengineering / Design Modification & Product enhancement from existing object for certification compliance and engineering practices.

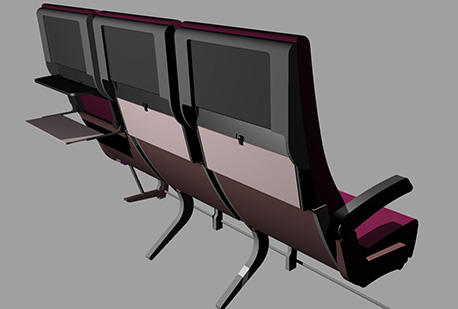

Aircraft Fuselage & Cabin Components Structural FEA Analysis (Static/Dynamic/Fatigue)

- In-Situ modelling and structural analysis of component integration in installation environment. Aircraft interior & exterior general Composites & Metallic Analysis with FEM & FEA.

- Structural analysis for seat track adapter plate designs with FEM & FEA for aircraft level installation work.

- Interface load analysis for 9g/16g Seat Installation on seat tracks with FEA.

- Structural analysis work for galley relocation with evaluation of aircraft hardpoint capability against the galley attachment points per effective TC holder generated principle structural documentation.

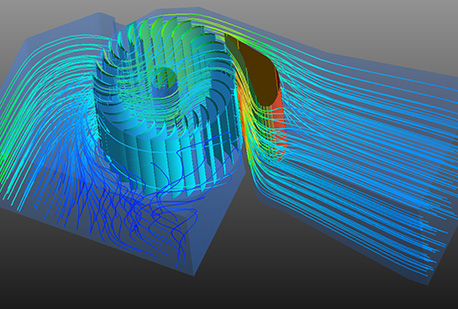

Aircraft & Gas Turbine Components- CFD Analysis (Thermal/Aerodynamic)

- Internal flow (subsonic/supersonic) in nozzles, diffusers and ducts. External flow over turbomachinery blades and wings with estimation of aerodynamic loads.

- Cooling Analysis for Compartment Design Selection.