We can provide you a customised engineering support for the certification packages in aircraft interior reconfigurations, external liveries, avionics upgrades etc with full Regulatory Compliance Standards (i.a.w FAA, EASA, NAA) and substantiation.

Our work scope in the issuance of technical documentation covers (but not limited to);

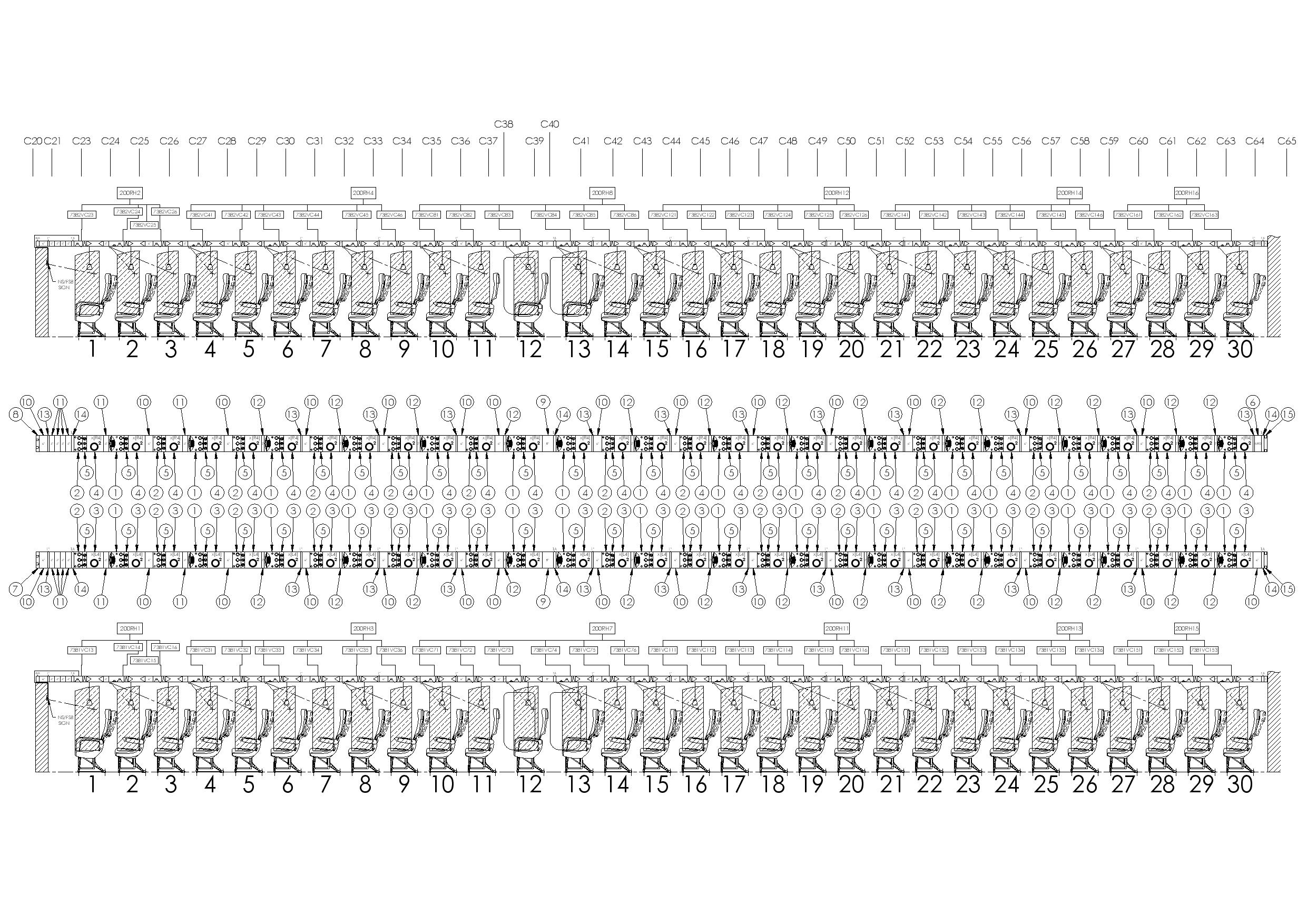

Cabin Reconfiguration

- LOPA, PSU & EEPMS changes.

- Seat PES and ISPS de-activation.

- Partition/MCD installation.

- Textile and Non-Textile Floor (NTFs) Covering Installation.

- Galley and Lavatory modifications and equipment installation.

- OHSB modification.

- EEL equipment assessment & installation.

- IFE, Lighting and Electrical Systems upgrade and installation.

- Partition wall laminate replacement.

- Partition wall decorative CREST removal/installation.

Support for STCs

- 9g/16g seat cushion changes at aircraft level.

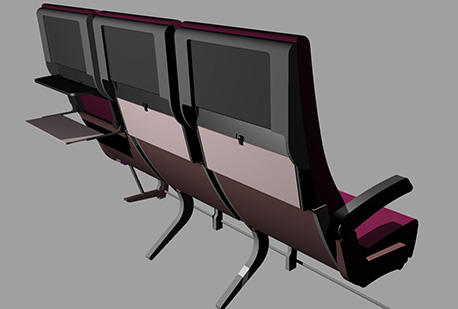

- Integration of new 9g/16g seat models into customer aircraft.

- Integration of new galleys, lavatories, stowages, closets and wardrobes into customer aircraft.

- New PES Audio & Video integration to new seat models.

- High quality Lithium battery installation approval for Emergency Locator Transmitter (ELT).

Avionics

- Structural and electrical analysis taking into account physical & functional characteristics.

- CAM Reprogramming for Airbus aircraft.

We can provide assistance with subcontracting of production work related to cabin interiors furnishing (internal/external pictorial & multilanguage placard printing, seat cover fabrication, curtain manufacturing, ownership plates and etc). All fabricated items will be shipped worldwide to the site of your choice.

Internal/External Placards & Markings

- All internal/external placards will conform to flammability rating requirements dictated under FAA, EASA & NAA regulations.

- We carry out fabrication of internal & external placards based on the existing AIPC/OEM/Part 21J approved modification packages.

- The placards can be issued individually or as a kit depending on customer preference.

External Decals/Stencils

- We undertake decal/stencil printing work for your custom graphic livery design.

- We will guide you at conceptual/design/production stages of your custom liveries.

- All our decal/stencil kits will be issued with a Certificate of Conformity or EASA Form 1.

- We can reproduce replacement decals on a quick turnaround at a very competitive cost.

We understand that the longer your aircraft stays on ground, the higher will be the losses in revenue generation. Therefore, it is our responsibility to provide you with an efficient repair solution to reinstate the airworthiness of the aircraft and release it back.

Our engineering team is highly experienced in providing support for developing temporary/permanent repair schemes (within & outside the TC Holder SRM Scope) for Airline Operators, MRO facilities and Subcontractors in a quick turnaround time (AOG or Standard Basis). We raise repair accomplishment work related to (but not limited to) the following areas (excluding primary aircraft structure);

- Engine lip & Acoustic liner repair procedures.

- Wings & Fuselage skin repair procedures in pressurised and unpressurised zones (Repair filler/doubler/tripler installations).

- Repair procedures related to dents, gouges and abrasions on fuselage top skin.

- Freeze plug installation.

- Fastener replacement.

- Structural corrosion removal and paint restoration generic procedures.

- Cosmetic (plastic) repairs for cabin interior equipment.

- Lavatory and Galley structural repairs.

- General/Visual/LFEC/HFEC inspection procedures related to structural damages.

- Seat Frame structural repairs.

We have delivered our engineering support to various airline operators in preparation of Repair Accomplishment Documentation, Work Orders, Damage Identification/Marking on Dent and Buckle Chart & etc.

We also offer the Structural Substantiation Compliance Assessment for the instructed repairs and structural evaluation when beyond the SRM limits using CAD software & FEA simulation packages to comply with the airworthiness regulations.

Our company can manage your conceptual to tender design by carrying out a preliminary critical feasibility review/assessment. This takes into account the component safety, reliability & maintainability in conjunction with airworthiness and applicable government regulations.

Beginning from the initial design stage through in-service support, a continuous support stream for improvement in operational costs and maintainability could be provided by us. This is accomplished by using engineering methodologies and tools that could establish a critical analysis of necessary performance standards and suggestions for innovative solutions.

Customers could also be assisted with component/part redesigns which occur due to obsolescence issues, refurbishments or upgrading. Support could also be given to create and interpret technical design documents, 2D/3D drawings & part/assembly modelling.

We combine client-specific knowledge of design & manufacturing processes while having an understanding of plastic, metallic and composite structures. Thereby, enabling us to provide you with pre-manufacturing support according to specifications and compliance to airworthiness guidelines for material choices, processes & tooling applications.

Mock-up Layout 3D Modelling

- Scaled 3D aircraft modelling for custom livery application.

- Custom layouts for exterior fuselage for identification of skin dents and other damages.

- Designing of stowage provisions for installation of portable oxygen bottles in closets/OHSB/CAS stations.

- Avionics & Electrical lines routing with structural mount installation provisions design.

Conceptual, Preliminary Design & Design to Manufacture of Aircraft Components.

- New Component Prototype modelling as per customer request & with all Certification Standards Compliance, Feasibility & Trade-off Studies, Weight/Cost reduction.

- Detailed geometry 2D Drawing & 3D Modelling using Reverse Engineering for As-Built Aircraft Components, MRO equipment & Custom Test Rigs.

- Legacy Part Reengineering / Design Modification & Product enhancement from existing object for certification compliance and engineering practices.

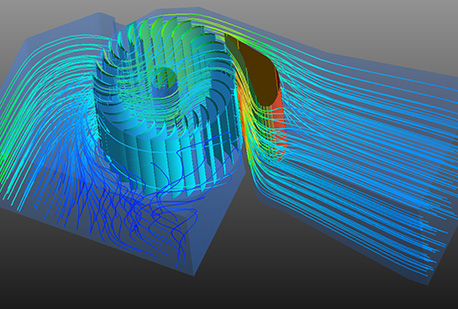

Aircraft Fuselage & Cabin Components Structural FEA Analysis (Static/Dynamic/Fatigue)

- In-Situ modelling and structural analysis of component integration in installation environment. Aircraft interior & exterior general Composites & Metallic Analysis with FEM & FEA.

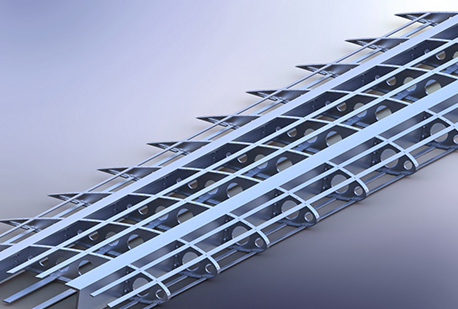

- Structural analysis for seat track adapter plate designs with FEM & FEA for aircraft level installation work.

- Interface load analysis for 9g/16g Seat Installation on seat tracks with FEA.

- Structural analysis work for galley relocation with evaluation of aircraft hardpoint capability against the galley attachment points per effective TC holder generated principle structural documentation.

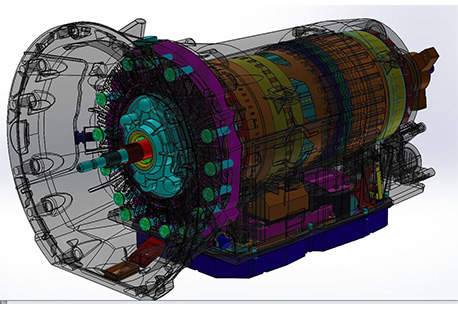

Aircraft & Gas Turbine Components- CFD Analysis (Thermal/Aerodynamic)

- Internal flow (subsonic/supersonic) in nozzles, diffusers and ducts. External flow over turbomachinery blades and wings with estimation of aerodynamic loads.

- Cooling Analysis for Compartment Design Selection.

Aviation Aftermarket Strategic Consulting

- Project Readiness Assessment

In the current aviation market, Project Readiness Assessment is a key factor to avoid unnecessary delays and budget shifts. Nevertheless, the proper project execution with well trained staff is the backbone to build up the client credibility and reputation in the aviation market. We have a great team of skilled engineering professionals who understand your custom requirements and scope of work at the initial phase and provide you with a cost-effective budget for your aircraft fleet. Therefore, the on-time project delivery to meet with the planned maintenance slots will be met by our design team. - Certification Program Management

Every minor/major modification or repair requires an essential strategic program at the initial phase to achieve the required business outcome that would be beneficial for the operator and design organisation. At Envol Technics, our clients are briefed on each project at contract review stage, preliminary stage, critical design review stage and final approval stage. This enables our clients to have a comprehensive understanding of the project flow and its progress from initial to delivery stage. - Manufacturing Processes Control

In the aviation market, it is mandatory to ensure that clients are provided with the correct parts and appliances corresponding to approved level of safety of Type Certificate holder and regulatory authority. We provide technical consultation support for the selection of correct process specifications. We can present you a compliance matrix for required airworthiness guidelines for materials, manufacturing processes & calibration requirements for tools and equipment. - Supplier Evaluation and Product Quality Control

The end quality of a part or appliance is dependent upon the manufacturing process chain and quality assurance system followed by the OEM. The majority of Airline Operators, MROs and Lessors procure parts and appliances from various suppliers or directly from the OEMs. The assurance of a part or appliance meeting the required minimum qualifying standards when sold in the aviation market is a challenging factor. Envol Technics relieves our clients of this responsibility and carries out the required investigations/audits on the OEM in order to identify their quality system and production processes so as to verify if the component could meet the minimum aviation quality and safety standards. - Remote Assistance

Off-Site technical support can be given to liaise with the customer’s personnel on maintenance location during embodiment of any system upgrades, retrofitting of equipment & any other relevant modification carried out on the aircraft. This includes required engineering feedback for the repaired components, on-site installation/testing/inspection instructions during a retrofitting procedure. In addition, Envol Technics could provide backing with troubleshooting of installation assemblies and operational problems.